Industrial Coffee Grinder Guide: Increase Efficiency and High Quality

In the competitive landscape of coffee production, selecting the right industrial coffee grinder plays a critical duty in improving both efficiency and product quality. Understanding the nuances of various mill kinds and crucial attributes-- such as adjustable work settings and robust construction-- can substantially affect the final flavor profile of the coffee.

Understanding Mill Kinds

When picking an industrial coffee mill, comprehending the various kinds offered is essential for optimizing both taste extraction and functional efficiency. The 2 key kinds of grinders are blade mills and burr grinders.

Inevitably, selecting the ideal sort of grinder is integral to preserving top quality and efficiency in coffee production, making it necessary for organizations to spend in high-quality burr mills for ideal results.

Secret Attributes to Consider

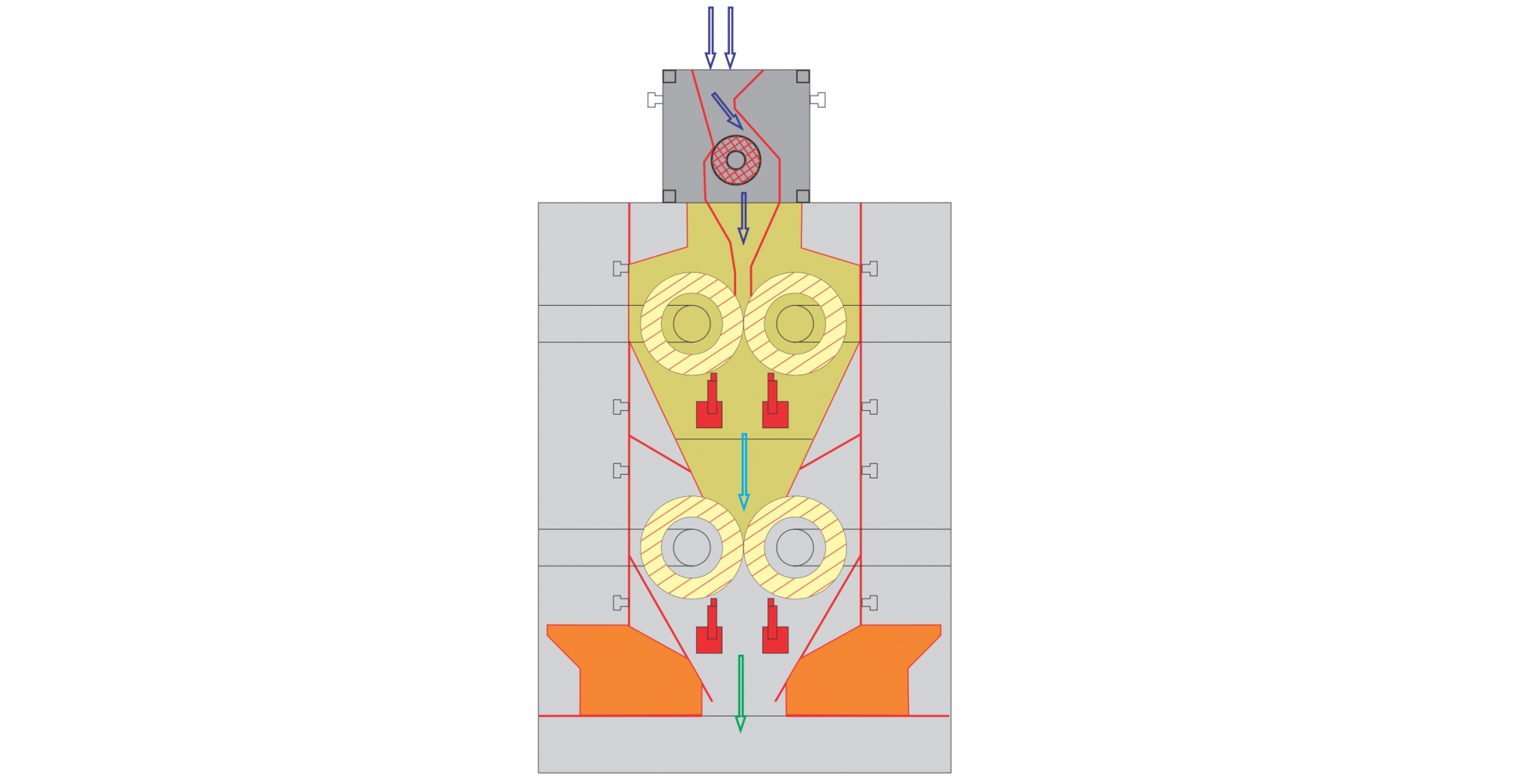

Selecting a commercial coffee grinder needs mindful consideration of several key features that can substantially affect both efficiency and the overall coffee experience. Among the primary aspects to assess is the grinding mechanism. Burr grinders are normally liked over blade grinders, as they supply a consistent work size, which is crucial for ideal removal and flavor.

Another important function is the mill's capability. A versatile mill with numerous settings permits you to tailor the grind dimension to various brewing approaches, boosting the coffee's taste profile.

Assess the grinder's sound degree, particularly in an active café or manufacturing atmosphere, where too much sound can be disruptive. Investing in a grinder that balances these functions can significantly boost both functional efficiency and the high quality of the coffee served.

Optimizing Grinding Refine

To achieve the very best cause coffee preparation, maximizing the grinding process is essential. The grind dimension dramatically influences removal, flavor, and general quality of the made coffee. Different developing techniques require details grind sizes; as an example, coffee demands a fine grind, while French press necessitates a coarse appearance. Recognizing the partnership between grind size and brewing method is the primary step in optimization.

Furthermore, monitoring the grinding rate can optimize the procedure. Slower grinding typically generates less warmth, maintaining delicate tastes and scents. Conversely, quicker grinding may produce too much warmth, negatively impacting the coffee's quality.

Maintenance and Treatment Tips

Appropriate upkeep and care of industrial coffee mills are vital for guaranteeing optimal efficiency and durability. Routine cleansing is the foundation of maintenance; deposit build-up can affect taste and grinding performance. It is a good idea to clean the mill after each usage, wiping down the exterior and eliminating any kind of coffee premises from the burrs.

In addition, inspect the grinding burrs for deterioration. Plain burrs can endanger grind uniformity, so they ought to be changed as required. Industrial Coffee Grinder. Regularly adjusting the mill is additionally vital, as this informative post keeps the desired work dimension for numerous developing techniques

Lubrication of moving parts must be done according to the manufacturer's specs, as this minimizes rubbing and lengthens the life of the devices. It is essential to use food-grade lubricating substances to ensure safety and security and compliance with wellness regulations.

Last but not least, maintain the grinder in a secure and completely dry setting to avoid rust and rust. By adhering to these upkeep and care ideas, operators can boost the efficiency of their commercial coffee grinders while making sure top notch output and expanded operational life.

Return on Financial Investment Analysis

Assessing the roi (ROI) for commercial coffee grinders is critical for companies looking for to enhance their coffee production abilities. A comprehensive ROI evaluation aids figure out the financial feasibility of purchasing premium mills, enabling organizations to consider the first expenses versus potential gains.

To perform a comprehensive ROI evaluation, businesses should consider numerous key variables. Initially, assess the you can try here acquisition rate of the grinder, consisting of installment and any kind of needed adjustments to existing framework. Next off, calculate operational expenses, including energy usage, upkeep expenditures, and labor performance renovations. High-performance mills usually result in lowered grinding time and raised throughput, which can considerably boost productivity.

In addition, consider the effect on item top quality. Industrial Coffee Grinder. Superior grinders generate an even more constant work size, which can enhance flavor accounts and client complete satisfaction, ultimately driving sales. By raising the top quality of the final product, businesses can warrant higher prices, resulting in boosted revenue

Final Thought

In summary, an industrial coffee grinder plays a pivotal role in boosting both effectiveness and product high quality within coffee manufacturing. Inevitably, the critical investment in a reliable mill adds dramatically to improved earnings and competitiveness in the coffee industry.

In the competitive landscape of coffee production, selecting the appropriate commercial coffee mill plays an essential function in enhancing both effectiveness and item quality. The 2 primary types of mills are blade mills and burr grinders. Within the burr mill classification, there are flat burr grinders and cone-shaped burr mills, each with its benefits. Burr grinders are typically chosen over blade mills, as they give a constant grind size, which is essential for optimum removal and taste.

In recap, a commercial coffee grinder plays a pivotal role in improving both performance and item top quality within coffee manufacturing.